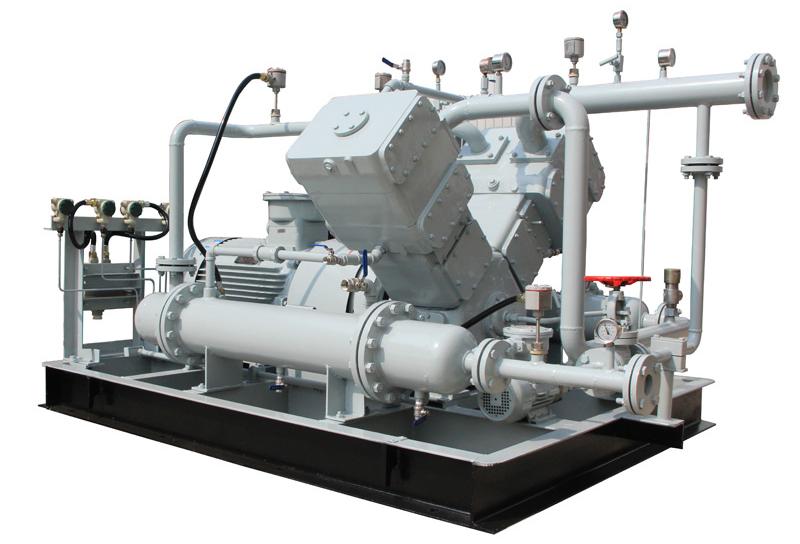

Piston gas compressors (reciprocating compressors) tau dhau los ua cov cuab yeej tseem ceeb hauv kev lag luam roj compression vim lawv cov zis siab, tswj tau yooj yim, thiab kev ntseeg tau tshwj xeeb. Kab lus no tau piav qhia txog lawv cov txiaj ntsig zoo hauv ntau hom roj compression scenarios, raws li cov qauv tsim qauv.

I. Core Structural Design

Kev ua tau zoo ntawm piston gas compressors stems los ntawm ib qho kev sib koom ua ke ua ke, suav nrog cov hauv qab no tseem ceeb:

1. High-Strength Lub tog raj kheej los ua ke

Tsim los ntawm cam khwb cia hlau, hlau alloy, los yog cov ntaub ntawv tshwj xeeb txheej los tiv thaiv corrosion mus sij hawm ntev los ntawm kev tawm tsam hnyav xws li acidic gases (xws li, H₂S) thiab cov pa oxygen siab.

Integrated dej / roj txias raws kom meej tswj qhov kub thiab txias hloov pauv los ntawm cov khoom siv roj (xws li, tsis muaj viscosity ntawm hydrogen, siab reactivity ntawm ammonia).

2. Multi-Material Piston Assembly

Piston Crown: Cov khoom xaiv raws li cov khoom siv roj-xws li, 316L stainless hlau rau sulfur-muaj roj corrosion kuj, ceramic coatings rau high-temperature CO₂ ib puag ncig.

Sealing Ring System: Siv graphite, PTFE, los yog hlau sib txuas cov ntsaws ruaj ruaj los tiv thaiv kom tsis txhob muaj cov pa hluav taws xob siab (xws li, helium, methane), kom ntseeg tau tias compression efficiency ≥92%.

3. Intelligent Valve System

Dynamically kho kom haum / tso pa tawm lub sij hawm thiab nqa kom haum raws li cov pa sib txawv thiab compression piv (piv txwv li, nitrogen ntawm 1.5: 1 rau hydrogen ntawm 15: 1).

Fatigue-resistant valve daim hlau tiv taus kev caij tsheb kauj vab ntau zaus (≥1,200 cycles / feeb), ncua kev txij nkawm nyob rau hauv qhov chaw muaj hluav taws kub / tawg.

4. Modular Compression Unit

Txhawb nqa tau yooj yim 2- mus rau 6-theem compression configurations, nrog ib-theem siab mus txog 40-250 bar, ntsib ntau yam kev xav tau los ntawm inert gas cia (xws li, argon) rau syngas pressurization (xws li, CO + H₂).

Kev sib txuas ceev ceev ua kom muaj kev hloov pauv ceev ceev raws li hom roj (xws li dej txias rau acetylene, roj txias rau Freon).

II. Muaj Gas Compatibility Zoo

1. Tag nrho Media Compatibility

Corrosive Gases: Txhim kho cov ntaub ntawv (xws li, Hastelloy cylinders, titanium alloy piston rods) thiab deg hardening kom durability nyob rau hauv sulfur- thiab halogen-nplua nuj ib puag ncig.

High-Purity Gases: Roj-dawb lubrication thiab ultra-precision filtration ua tiav ISO 8573-1 Chav Kawm 0 kev huv rau cov khoom siv hluav taws xob-qib nitrogen thiab kev kho mob oxygen.

Flammable / Explosive Gases: Ua raws li ATEX / IECEx cov ntawv pov thawj, nruab nrog cov hluav taws kub hnyiab thiab lub siab hloov pauv dampers rau kev nyab xeeb ntawm hydrogen, oxygen, CNG, thiab LPG.

2. Adaptive ua hauj lwm muaj peev xwm

Dav Flow Range: Kev sib txawv-zaum tsav thiab tshem tawm qhov ntim hloov kho kom muaj kev tswj xyuas cov kab khiav tawm (30% -100%), haum rau kev sib tshuam ntau lawm (piv txwv li, cov tshuaj cog cov pa rov qab) thiab cov khoom siv tas mus li (xws li, cua sib cais units).

Smart Control: Integrated gas composition sensors pib-kho tsis tau (xws li, qhov kub thiab txias, lubrication tus nqi) los tiv thaiv malfunctions tshwm sim los ntawm dheev gas vaj tse hloov.

3. Kev siv lub neej zoo

Kev Txhim Kho Tsawg Tsawg: Cov khoom tseem ceeb ntawm lub neej txuas ntxiv los ntawm> 50% (piv txwv li, 100,000-teev crankshaft txij nkawm), txo qis qis hauv qhov chaw muaj kev phom sij.

Energy Optimization: Compression curves tailored rau gas-specific adiabatic indices (k-values) ua tau 15% -30% kev txuag hluav taws xob piv rau cov qauv qub. Piv txwv li:

Cua compressed: Tshwj xeeb zog ≤5.2 kW / (m³ / min)

Natural gas boosting: Isothermal efficiency ≥75%

III. Cov Ntawv Thov Kev Lag Luam tseem ceeb

1. Standard Industrial Gases (Oxygen / Nitrogen / Argon)

Hauv cov hlau metallurgy thiab semiconductor manufacturing, roj-dawb tsim nrog molecular sieve tom qab kev kho mob kom 99.999% purity rau daim ntaub ntawv xws li molten hlau shielding thiab wafer fabrication.

2. Zog Gases (Hydrogen/Syngas)

Multi-theem compression (txog 300 bar) ua ke nrog kev tawg ntho cov tshuab ua kom muaj kev nyab xeeb ntawm hydrogen thiab carbon monoxide nyob rau hauv lub zog cia thiab tshuaj synthesis.

3. Corrosive Gases (CO₂/H₂S)

Customized corrosion-resistant solutions-xws li, tungsten carbide coatings thiab acid-resistant lubricants-address sulfur-rich, high-humidity condition in oilfield reinjection and carbon capture.

4. Tshwj xeeb Electronic Gases (Fluorinated Compounds)

Kev tsim kho tag nrho thiab helium mass-spectrometer leak detection (kawg tus nqi <1 × 10⁻⁶ Pa·m³ / s) xyuas kom muaj kev nyab xeeb ntawm cov pa phem xws li tungsten hexafluoride (WF₆) thiab nitrogen trifluoride (NF₃) hauv photovoltaic thiab IC industries.

IV. Kev Tsim Kho Kev Tsim Kho Tshiab

Digital Twin Systems: Real-time data modeling predicts piston ring wear and valve failures, enabling care alerts 3-6 lub hlis ua ntej.

Green Process Integration: Cov khoom khib nyiab rov qab los hloov 70% ntawm compression cua sov rau hauv chav lossis hluav taws xob, txhawb nqa cov hom phiaj ntawm cov pa roj carbon monoxide.

Ultra-High-Pressure Breakthroughs: Pre-stressed winding lub tog raj kheej thev naus laus zis ua tiav ib-theem compression> 600 bar hauv chaw kuaj sim, paving txoj kev rau yav tom ntej hydrogen cia thiab thauj.

Xaus

Piston gas compressors, nrog lawv cov qauv tsim qauv thiab cov peev xwm kho tau, xa cov kev daws teeb meem txhim khu kev qha rau kev lag luam roj. Los ntawm kev niaj hnub compression mus rau qhov xwm txheej tshwj xeeb ntawm cov roj siv hluav taws xob, kev ua kom zoo ntawm cov qauv ua kom muaj kev nyab xeeb, ua haujlwm tau zoo, thiab ua haujlwm zoo.

Rau cov lus qhia kev xaiv compressor lossis cov ntawv tshaj tawm txog kev siv tau raws li kev tshaj tawm roj av, thov hu rau peb pab pawg engineering.

Technical Notes:

Cov ntaub ntawv muab los ntawm ISO 1217, API 618, thiab lwm yam kev xeem thoob ntiaj teb.

Kev ua tau zoo tiag tiag yuav txawv me ntsis nyob ntawm cov roj muaj pes tsawg leeg thiab ib puag ncig.

Cov cuab yeej teeb tsa yuav tsum ua raws li cov cai tswj kev nyab xeeb hauv zos rau cov cuab yeej tshwj xeeb.

Post lub sij hawm: May-10-2025